Health Industry & Pharma

1. Medical Device Engineering

With extensive expertise, we provide efficient and innovative medical device engineering solutions. Our comprehensive services cover every stage of development, from concept initiation to production and post-market evaluation.

Focusing on continuous innovation, we go beyond expectations. Our collaboration with Quality Management and Regulatory Affairs ensures seamless compliance and outstanding results.

NOBLE HOME HK Health Quality

Our dedication to quality is unwavering. We proudly uphold ISO 13485 certification, demonstrating our adherence to strict industry standards.

Noble Home HK Health offers adaptable product development services, spanning feasibility analysis, conceptual design, and testing. Our expertise extends to prototype creation, testing facilitation, and streamlining designs for manufacturing.

We assist in securing FDA and CE certifications while providing robust post-market monitoring. Clients can tailor our engineering and manufacturing services to align with their specific needs.

Conceptualization

At the outset, we establish product specifications, conduct market research, and, when applicable, initiate patent applications. A feasibility study is performed to assess project viability.

Design & Development

In this phase, we refine designs using a variety of methodologies, ensuring tailored solutions for our clients. Our expertise allows us to manage the entire development process, helping clients achieve swift market entry and regulatory approvals for Europe and the U.S. Additionally, we oversee biomechanical and chemical testing to ensure compliance with all relevant standards.

FEM Analysis & Topology Optimization

To create intelligent, efficient, and high-performing solutions, we employ finite element analysis techniques. We further optimize component topology to streamline manufacturing, minimize weight, and reduce costs and production time.

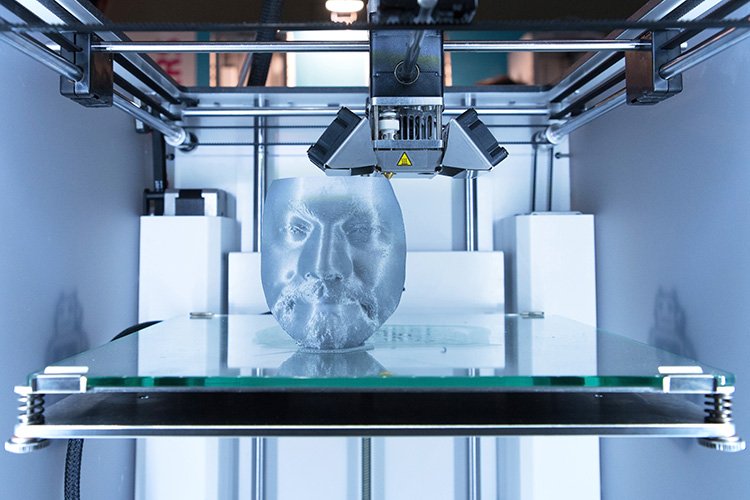

Prototyping

Throughout both the conceptual and design phases, we provide initial prototypes for visual and functional evaluation via customer feedback or Cadaver Lab testing. Our in-house 3D printing capabilities, along with an extensive supplier network, allow us to deliver rapid and effective support.

Qualification & Compliance

Quality assurance is integral at every development stage. Our dedicated quality and regulatory team ensures full compliance, guiding clients through regulatory approvals in both European and U.S. markets. We coordinate all required biomechanical and chemical testing.

Serial Production

Leveraging our extensive network, we transform 2D and 3D designs into market-ready products. As an accredited contract manufacturer, we manage production setup, cost estimations, inspections, and comprehensive documentation, ensuring a seamless transition to manufacturing.

Post-Market Monitoring

Our highly detailed anatomical models enhance medical training and surgical planning, offering realistic representations for more effective teaching and treatment strategies.

Get in touch with us for:

Medical Device Engineering

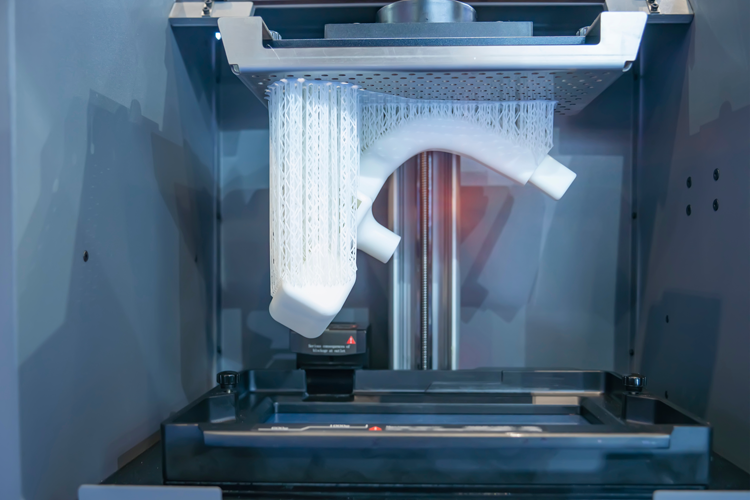

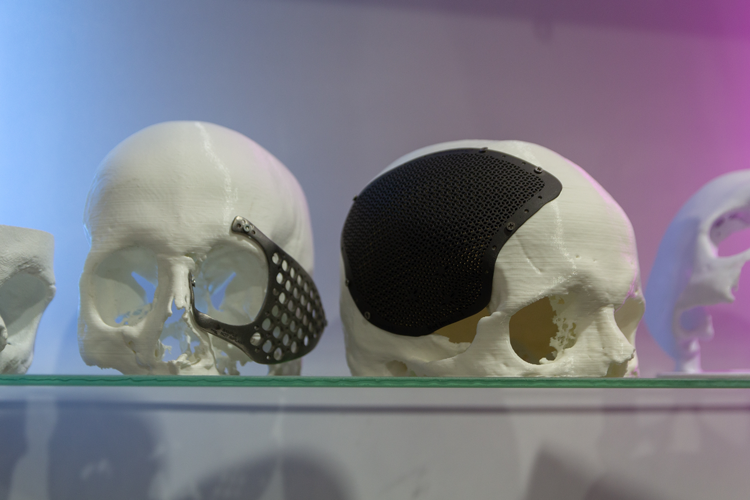

3D Printed Medical Devices

The availability of advanced 3D printing technologies and a broad selection of materials allows us to address a wide range of needs.

This includes everything from prototype creation and instrument fabrication to implant development, specialized tooling, and various medical device production.

- Verified Suppliers

For 3D printing technologies not currently available in-house, we collaborate with a trusted network of suppliers to ensure access to the highest-quality materials and cutting-edge printing technologies. This extensive network enables us to offer diverse solutions tailored to your specific requirements.

- Fast Delivery

Our streamlined processes and efficient logistics ensure rapid delivery of 3D-printed components. Whether you require a single prototype or a full production batch, we prioritize meeting your deadlines with reliability and precision.

- Competitive Pricing

We recognize the significance of cost-effectiveness in the medical industry. That’s why we focus on providing competitively priced 3D printing services. By optimizing our supply chain and leveraging our supplier partnerships, we deliver cost-efficient solutions without compromising on quality.

Material & Technology

We provide a wide selection of materials and state-of-the-art 3D printing technologies. Our options include biocompatible resins, durable thermoplastics, stainless steel, and titanium, catering to a broad spectrum of medical applications.

3D Printing

Our process involves constructing objects layer by layer from digital 3D models, offering exceptional design flexibility. Noble Home HK Health specializes in high-precision printing services for custom medical devices, prototypes, anatomical models, and tools.

This method allows us to create intricate geometries, develop prototypes without costly tooling, and customize designs for patient-specific anatomies using medical-grade materials. Contact us to see how our 3D printing expertise can enhance your medical projects.

- 3D Print Technical Data

Depending on the chosen technology, we provide a range of accuracy levels and material properties. Whether you need ultra-fine details or high structural integrity, our technical expertise ensures superior quality in every print.

- Our Materials

We offer a variety of premium materials designed for medical applications, including biocompatible resins, strong thermoplastics, and specialized materials for functional parts, prototypes, anatomical models, and tools.

- File Formats

We support a wide array of file formats to ensure compatibility with various design software and workflows. Commonly accepted formats include STL, OBJ, and STEP, simplifying the integration of your designs into our 3D printing pipeline.

- Manufacturing

Our additive manufacturing process is optimized for accuracy and efficiency. From file preparation and slicing to printing and post-processing, we adhere to stringent quality control measures to ensure consistency and reliability. Our experienced team ensures that every component meets your exact specifications.

The Technique Behind 3D Printing

Functional Model & Services

FDM (Fused Deposition Modeling)

FDM is a widely used 3D printing technique that extrudes thermoplastic filaments layer by layer to create objects. Known for its affordability and versatility, it supports a range of materials, from standard polymers to flexible and high-performance composites. Popular choices include PLA, PETG, and ABS.

MJM (Multijet Modeling)

Blend of Materials & Hues

MJM employs multiple jets to selectively deposit photopolymer material onto a build platform, with each layer cured using UV light. This method enables high-resolution printing with intricate details, making it ideal for precise prototypes and complex models.

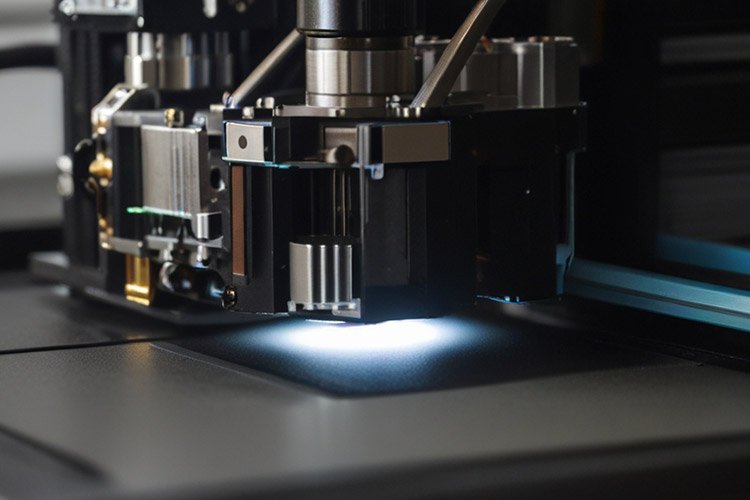

SLA (Stereolithography)

For Components with Complex Shapes

SLA uses a UV laser to cure liquid resin layer by layer, producing highly detailed and accurate parts with smooth finishes. With its broad range of compatible materials, including biocompatible resins, SLA is particularly suitable for applications requiring intricate geometries and medical-grade properties.

SLS (Selective Laser Sintering)

Powder-Based 3D Printing

SLS employs a laser to fuse powdered materials, such as nylon, into robust, durable components. This technology excels in creating complex geometries without requiring support structures, making it ideal for functional prototypes and end-use medical parts. SLS materials offer excellent strength, heat resistance, and chemical resilience.

SLM (Selective Laser Melting)

Printing Method

SLM operates similarly to SLS but is specifically designed for metal powders. A high-powered laser melts and fuses metal particles layer by layer, producing fully dense, high-strength metal components suitable for demanding medical applications.

BJ (Binder Jetting)

Printing Method

Binder Jetting involves selectively depositing a liquid binder onto a powder bed, bonding the particles together layer by layer. Once printing is complete, the excess powder is removed. This technique is commonly used for manufacturing prototypes, sand molds, and metal parts.

Get in touch with us for:

3D Printed Medical Devices

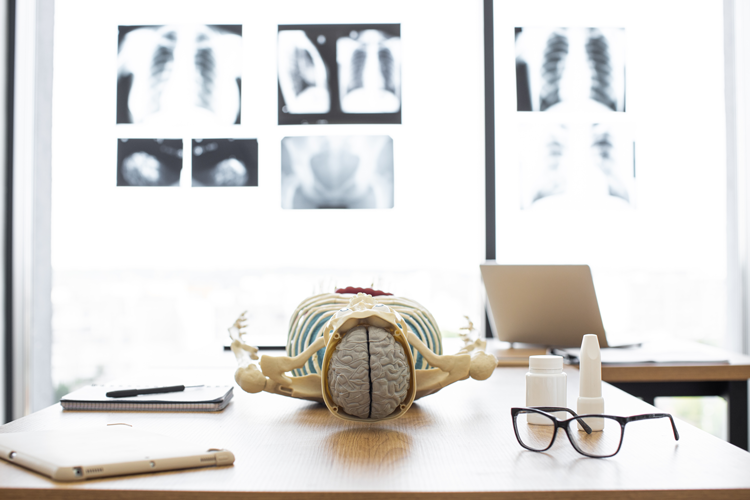

Anatomical Models

Discover Our High-Quality Anatomical Models

Ideal for medical training programs and precise surgical planning. Enhance your teaching methods and treatment strategies with our realistic and customized solutions.

- Availability and Cost Efficiency

One key advantage is the instant availability of 3D-printed models for training purposes. Unlike traditional methods, these models are ready to use at any time and are more cost-effective to produce and acquire.

- Flexibility and Ethical Aspects

3D-printed anatomical models offer unparalleled flexibility for medical training without ethical constraints. These models can be used for hands-on exercises in various settings like meeting rooms or hotels, providing a versatile training environment.

- Training Opportunities

Medical professionals can conduct practical training on these models in settings such as meeting rooms or hotels, offering a portable and convenient solution for medical education.

- Personalization and Reproducibility

Customized models can be tailored to specific patient cases, allowing for precise anatomical representation and simulation of medical scenarios. Additionally, these models can be replicated with accuracy, ensuring consistent training conditions across sessions.

Printing Technology

Our PolyJet printing services specialize in creating highly detailed anatomical models. Using advanced technology, we can produce lifelike replicas of human anatomy, including organs, bones, and tissues, with precise textures and colors.

PolyJet printing allows us to achieve exceptional realism and accuracy in anatomical models, making them invaluable for medical education, surgical planning, and patient communication. Each model is customized to replicate specific patient anatomy, enhancing its utility and relevance in medical practice.

Medical Education and Forensic Science

Anatomical models play a crucial role in both medical education and forensic science. They offer a tangible and interactive approach for studying human anatomy, aiding in the comprehension and retention of anatomical structures among students and healthcare professionals.

Additionally, in forensic science, these models are used to analyze injuries, conduct facial reconstructions, and reconstruct crime scenes. They assist experts in understanding trauma patterns, identifying remains, and recreating the appearance of individuals from skeletal remains or tissue structures.

Research and Development

Anatomical models are utilized in biomedical research and development to test new medical devices, evaluate treatment methods, and explore anatomical variations. These models provide researchers with a platform to conduct experiments and simulations in a controlled environment, leading to advancements in healthcare technologies and techniques.

Surgical Planning and Preoperative Rehearsal

Anatomical models are used by surgeons to plan and rehearse complex surgical procedures before operating on patients. By visualizing patient-specific anatomy in three dimensions, surgeons can develop precise surgical strategies, anticipate challenges, and optimize outcomes. This preoperative training enhances surgical accuracy and safety.

Get in touch with us for: